Materials

In manufacturing lockers we use aluminum composite panels and anodized aluminum profile.

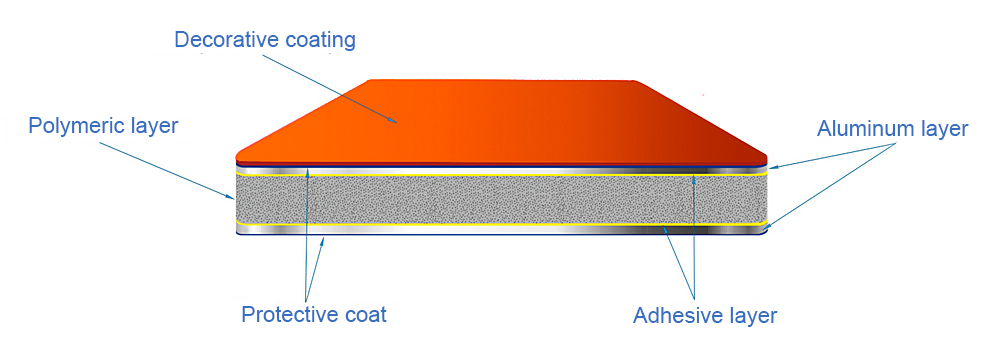

Aluminum composite panels (ACP) hhave a multilayered structure with aluminum sheets as principal layers and the polymeric filling material as an interlayer. The new material possesses better properties than the base materials separately. Durability, enhanced corrosion resistance and chemical stability are some of them.

Aluminum composite panels are also widely used as finishing and construction materials. They are employed for building cladding, outdoor advertising and in other fields

Aluminum profile is a light robust material, which properties allow to manufacture all complex engineering systems.

Advantages

Resistance to harsh environments, such as:Structural reliability.

Outer appearance and usability.

Easy transportation and assembly.

1. Harsh environments resistance

How is water resistance of “AquaLocker” Series lockers ensured?

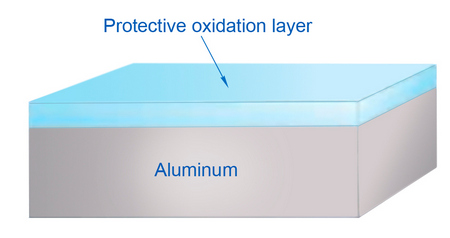

Aluminum undergoes the chemical process of anodizing, which means the creation of an oxide film by anodic polarization in a conductive medium. Anodizing provides resistance to corrosion and water. This property is natural for aluminum.

This material is also tolerant to such other harsh environments as ultraviolet, meaning that items manufactured from ACP may be used:

- in direct sunlight;

- under fluorescent lamps, which are now widely used to light the premises;

- in premises where germicidal ultraviolet lamps are used for air and surface disinfection.

can be washed with chemical detergents

The warranty period of aluminum panels with protective oxidation and laminated layers is 15-20 years, although actual years of service exceed 30 years. This is much longer than that of the lockers made of chipboard (less than 2 years) and of metal (on average 10 years without taking the impact of moisture.

2. Reliability of construction

Aqualocker lockers are designed with the consideration of all specifics of using them in swimming pools and water parks:

The frame made of aluminum profile provides reliability.

Robust aluminum composite panels don’t let the lockers bend or deform.

Our technology doesn’t allow the doors to sag which is ensured by the fastening technics as the hinges of our doors are part of the door itself.

The locks on the doors can be either electronic or mechanical. We use Bonwin electronic locks which can be chosen to your needs. They are user-friendly and durable.

Parts of Aqualocker lockers are manufactured on highly-accurate computer numeric control (CNC) machine providing accuracy and precision of measurements.

Minimum of fastening bolts made of stainless steel guarantee product life.

3. Exterior and Usability

Aqualocker lockers have nice and ergonomical design and all necessary components such as robust locks, internal partition walls, clothes hooks. The legs of the lockers enable to adjust the height.

ACP guarantee the finished product smart and reliable look. The material feels nice and smooth that makes it possible for our lockers to be used in children’s changing rooms.

4. Easy to transport and assemble

Aqualocker lockers made of ACP are easily assembled, they can be transported knock-down which significantly reduces the cost of transportation.

Lightness of the material plays an important role both in transportation and in assembling which takes no more than 10-20 minutes including the installation of the locks

For your convenience, our experts are ready to come and install the lockers and solve any problems that may arise.

Посмотреть модели Посмотреть видео